STÜWE – Third Party Machining

In addition to the standard range of shrink discs, frictional locking units, shaft couplings and cardan shaft connections, STÜWE also develops customised special solutions for your application.

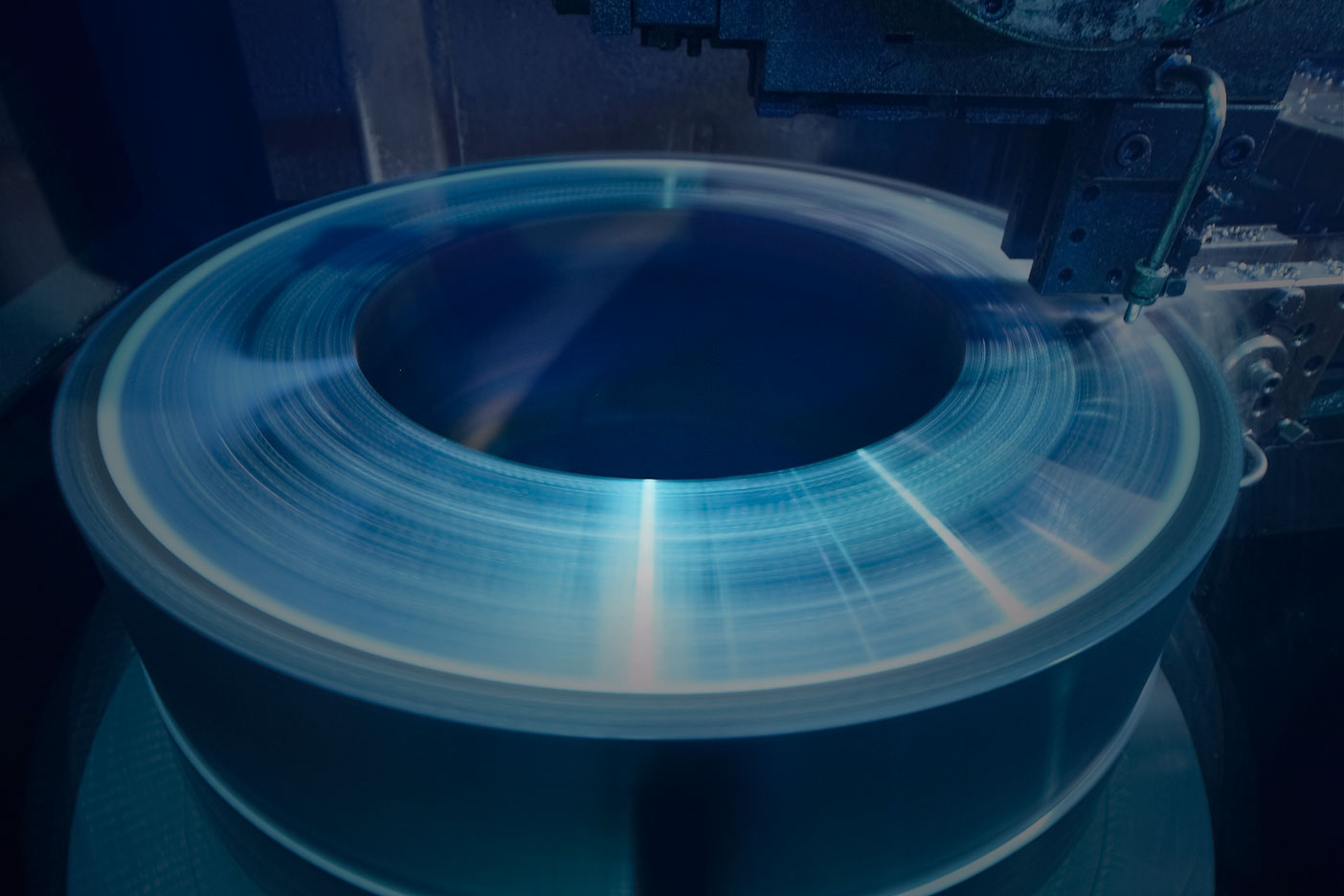

The company’s sophisticated machinery is able to create rotationally symmetrical components in a diameter of 20 mm to 2200 mm, a height of up to 1400 mm and with a maximum component weight of 10 tonnes. STÜWE uses extensive 3D measurement technology to directly check the manufactured components for dimensional accuracy.

Materials

As well as the standard use of heat-treated steel, STÜWE can also design and manufacture frictional connections from special materials such as 1.4501 and many other alloys.

Painting and Coating

STÜWE’s in-house paint shop offers you a very wide range of paint and coating options. All shrink discs can be painted with colours from the RAL spectrum and, if desired, an appropriate corrosion protection class in accordance with DIN EN ISO 12944. To ensure corrosion protection for the frictional connections, all shrink discs can also be provided with coatings such as nickel or zinc. Further coating processes are possible in consultation.

Product Certification

STÜWE’s experienced development team applies its technical and business standards in a skilled and efficient manner while taking into account quality features and the demands of certification bureaus. For this purpose, STÜWE works closely with various certifying organisations from the maritime industry and wind power sector.

Lubrication

In order to generate optimum friction coefficients, the lubricants used on STÜWE’s components are based as standard on mineral oils. As an alternative the company also offers modifications using NSF H1 classified lubricants permitted for use in applications where product contact cannot be fully excluded like the foodstuff, nutritional and pharmaceutical industries.